Scrap Straightening Machines

ACE Scrap Bar Straightening Machines are engineered to revive bent, twisted, or used rebars - turning scrap into reusable material. Built with a heavy-duty roller system and adjustable pressure mechanism, these machines are ideal for sustainable and cost-effective construction practices.

Key Features:

Heavy-duty rollers ensure smooth and efficient straightening

Adjustable pressure screw to suit various rebar sizes and conditions

Electrical components from top brands like Siemens and Schneider

Foot pedal operation for enhanced safety and control

Durable frame with compact design for easy site mobility

Benefits:

Reduces material wastage by reusing scrap

Enhances sustainability and cost savings

Delivers uniform straightening with minimal deformation

Safe and easy to operate with low maintenance needs.

Salient Features - Scrap Straightening Machines

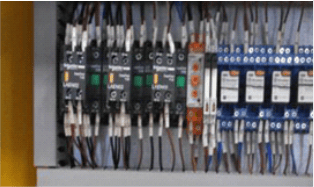

Electrical Components

- Top-brand electrical components such as controllers, timers, relays, and converters from Siemens and Schneider are used.

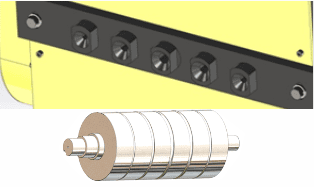

Bushes & Heavy Duty Roller

- Different diameters of bushes are used for various rod sizes, along with a heavy-duty roller for efficient straightening operations.

Pressure adjusting Screw

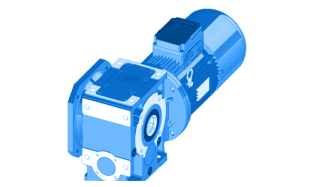

Helical Bevel Gear Box

- Helical Bevel Gearbox ensures outstanding power transmission efficiency, with 90% of input energy effectively transmitted.

- High torque and reduced load inertia, along with a gradual reduction in speed, extend the gearbox’s lifespan without jerks or sudden impacts.

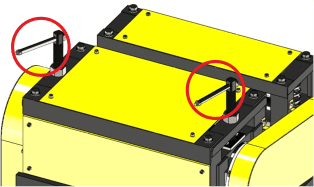

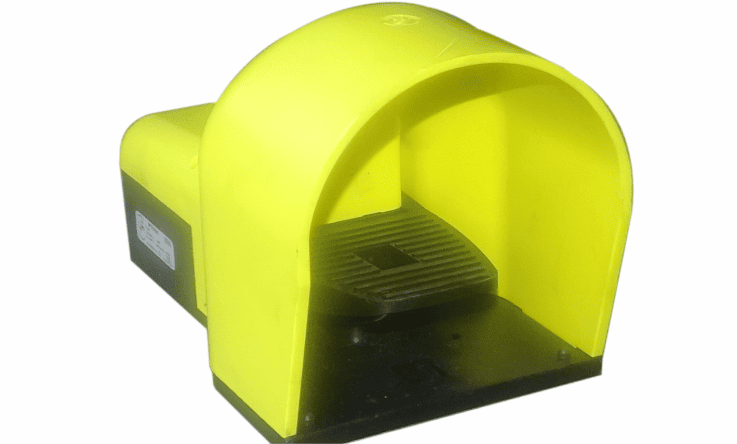

Foot Pedal

- The machine operates only when the foot pedal is pressed, ensuring controlled and safe operation.

- Once the foot is removed, the machine automatically stops, enhancing safety.

- Equipped with a foot guard cover for added protection against hazards at construction sites.

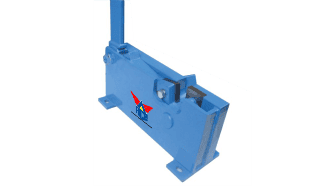

Manual Bar Cutting Machine

- Manual bar cutting machine is used to cut damaged end of the rod for easy entry in the bush.

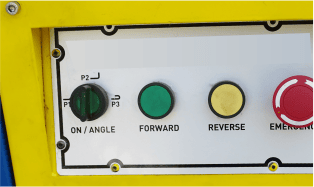

Forward & Reverse Switch

- A Forward & Reverse switch is provided for easy operation, allowing the user to control the direction of the rollers as needed.

- This feature ensures smooth handling of rods, preventing jams and enabling efficient straightening.

Heavy Duty Wheel

- Heavy-duty wheels are provided for easy transportation, allowing the machine to be moved effortlessly across different work sites.

| TECHNICAL SPECIFICATIONS | DETAILES |

| Dimension L X W X H | 1492 x 952 x 1337 mm |

| Machine Weight | 650 Kgs. |

| Out Put Speed | 25 m/min |

| Capacity Dia Ø | 8-14 mm |

| Gear Box | 4 kW |