Multi-Functional Hoists with Cage

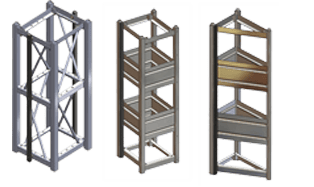

Multi-Functional Hoists with Rebar Carrying Attachment

Salient Features - Multifunctional Hoists

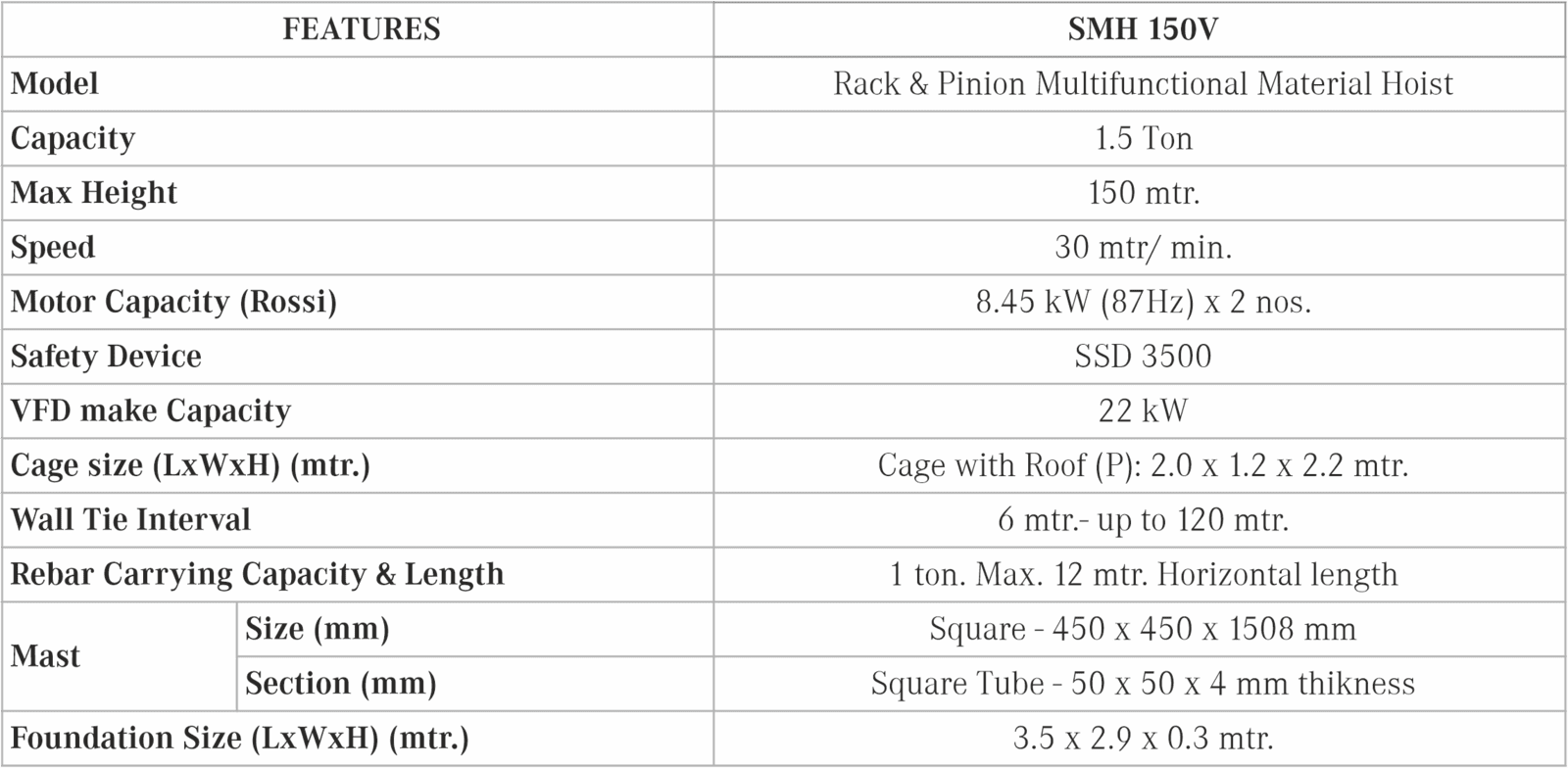

Hot-dip Galvanised Mast

- The mast structure is made from high-quality standard tubes with high-strength sheet metal bend angles, and hot-dip galvanization for long-lasting protection.

- The 6-module rack, made of high-tensile steel, ensures robust performance, precise gear engagement, and enhanced durability through galvanization

Wall Tie

The wall tie structure is made from high-quality standard tubes and reinforced with high-strength sheet metal bend angles.

Hot-dip galvanization provides excellent surface protection. Its telescopic design allows length adjustment to suit various building projections, ensuring greater flexibility and extended part life

Variable Frequency Drive - VFD

- The machine control panel is equipped with a VFD (Variable Frequency Drive) from globally recognized brands such as Schneider and Mitsubishi.

- Benefits: It ensures smooth motor operation by eliminating jerks, extends machine life, reduces maintenance needs, allows torque adjustments, and lowers energy consumption and operating costs.

Encoder Floor Selection

Floor selector is provided with encoder IP65 protection

Load Cell (Optional)

- A load cell is provided for overload protection in the machine.

- It detects excess load and immediately stops the machine, ensuring passenger safety during travel.

Base Enclosure

- The base enclosure of a multi-functional hoist plays a vital role in ensuring operational safety and equipment protection at the ground level.

- It is designed to offer a secure, enclosed area around the base of the hoist, preventing unauthorized access and reducing the risk of accidents.

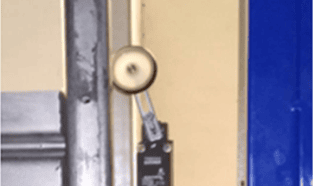

Limit Switch - Entry & Exit Door

These are electric interlock switches, which stop the cage to move up or down.

Operating Console/ Control Panel

- The control panel features clearly labeled push buttons for easy function identification.

- A fault display aids quick troubleshooting, while the HMI shows real-time machine status, including faults, running hours, floor position, and overload detection-ensuring safe, efficient operation

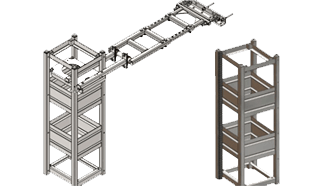

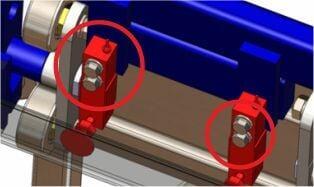

Rack Sensing Limit Switch

A rack-sensing limit switch is provided as an additional safety feature to detect the presence of the rack. It automatically stops the machine if the rack is missing, ensuring safe operation.

Top, Bottom & Final Limit Switches

Limit switches used in the machine control panel are sourced from globally recognized brands such as Schmersal and Teknic. They offer high durability, easy availability, smooth operation, and excellent reliability.

European Geared Motor

European-made, energy-efficient IE2 motors are used, offering reduced running costs, extended motor life, and international warranty coverage.

Safety Device

European design safety device with latest four-point contact lock to prevent cage from free fall. It is automatic reset safety device hence no need to open safety device for resetting at site.

Cage for Carrying multiple Materials

Sanitary ware Items

Bricks/ Concrete Blocks

Concretes Trolly

Glasses

Rebar Stirrups

Marbles/ Tiles

Building Materials

Passengers

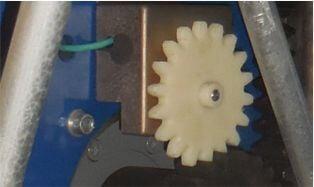

Technical Specifications - Multi-functional Hoists