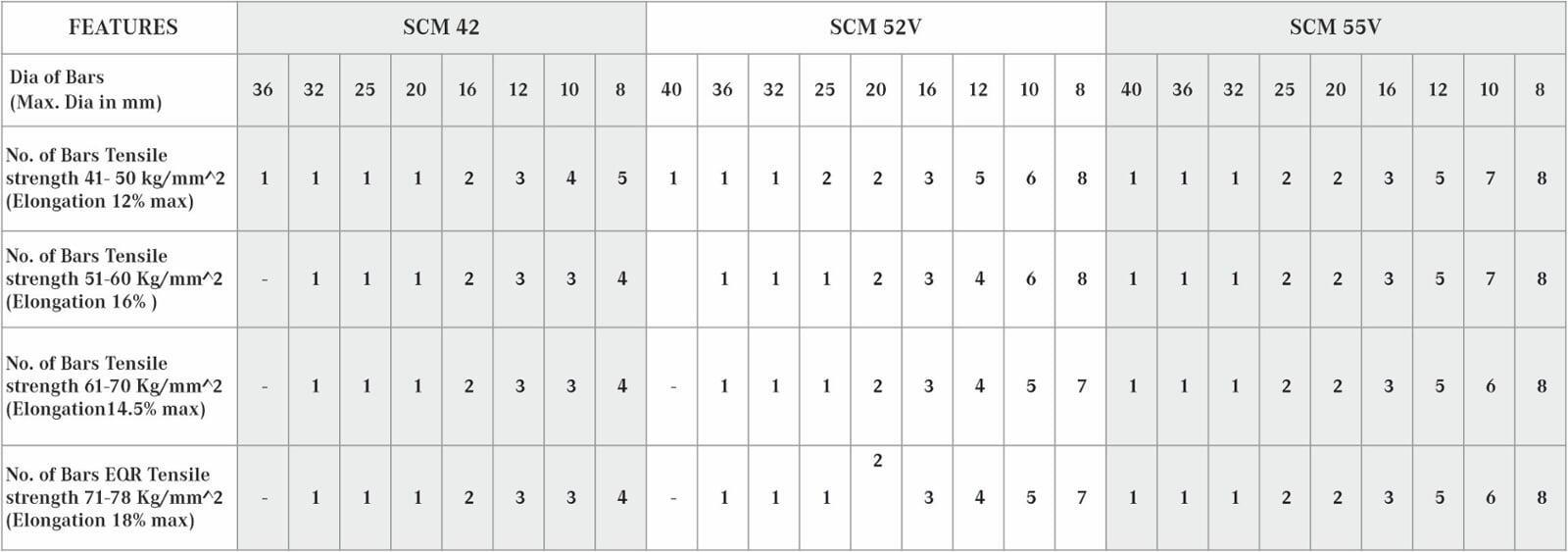

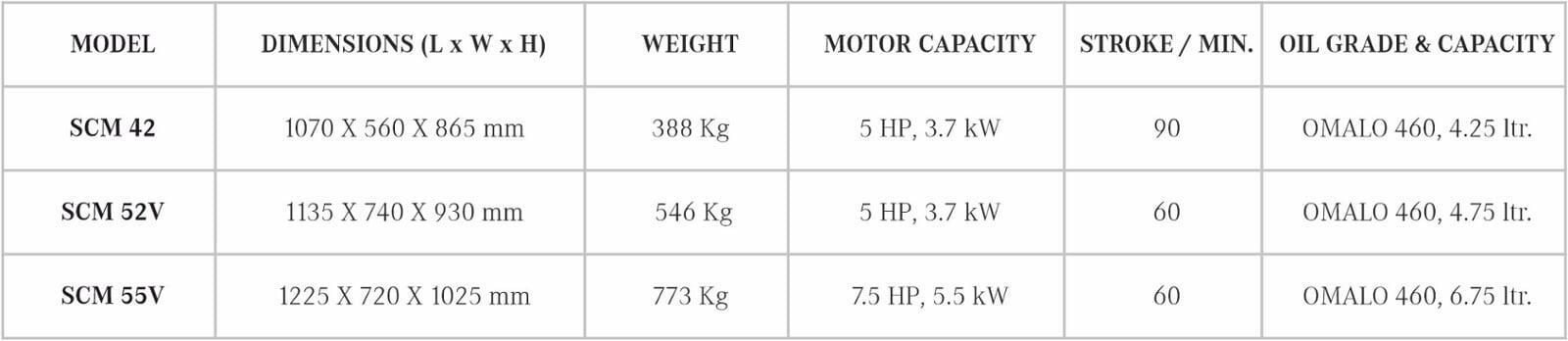

Bar Cutting Machines - SCM 42

Bar Cutting Machines - SCM 52V

Bar Cutting Machines - SCM 55V

Salient Features - Bar Cutting Machines

Machine Body

- The body is made of high-quality steel and treated with a 7-tank process for strong powder coat bonding.

- Finished with PP (pure polyester) powder coating, it offers a superior finish, corrosion protection, and reduced maintenance costs.

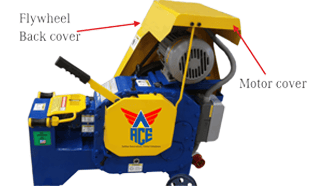

Flywheel and Motor Cover

- Completely enclosed flywheel cover ensures operator safety during operation.

- Full motor cover protects the motor from rain, dust, and debris commonly present at construction sites.

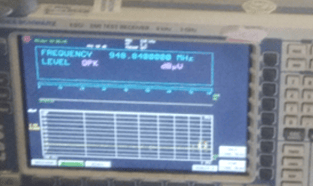

Electric Panel with testing LV, HV

- LV-HV Test: Conducted to ensure the durability and sustainability of electrical components.

- Emission Test: Conducted to confirm that emissions are within permissible limits, posing no harm to the operator or the environment.

- Results: Zero breakdowns reported; tests were conducted by an authorized government testing body.

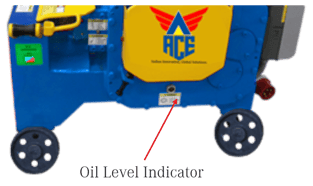

Oil Level Indicator

- Oil level indicator provided for easy monitoring.

- Strategically positioned at the bottom for clear visibility.

- Helps maintain proper oil levels, preventing damage to internal parts.

- Reduces downtime and enhances overall machine performance.

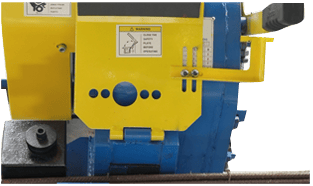

Mechanical Interlock

- Interlock prevents machine use unless safety plate is closed, ensuring operator safety. Metal handle with grip allows comfortable handling.

- Ergonomic grip handle enables easy and comfortable operation.

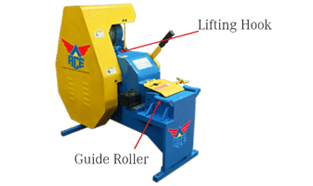

Guide Roller & Lifting Hook

Guide Roller:

- Facilitates smooth and hassle-free handling of bars during operation.

- Provides support while measuring and marking the bars.

Lifting Hook:

- Equipped with a lifting hook for easy handling and transportation of the machine.

High Strength Spring

- A heavy-duty spring is used as the Hand Lever Return Sparing.

- It maintains elasticity for a long time. This helps to reduce downtime and improve the productivity.

Safety Plate

- Prevents bars from flying after cutting, ensuring operator safety.

- Equipped with a mechanical interlock that inhibits blade operation when the safety plate is open, preventing accidental activation.

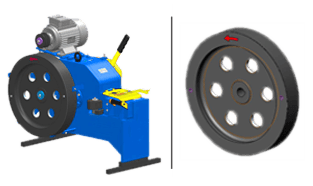

Flywheel Diameter

- Flywheel diameter increased to deliver maximum power, resulting in 1.5 times higher moment of inertia.

- Enhanced stroke impact power ensures effortless cutting of high-tensile rebars.

- Ready to handle advanced high-tensile steel, making it suitable for demanding construction needs.

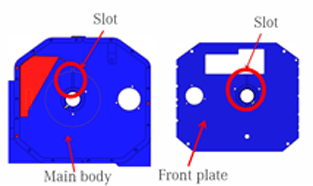

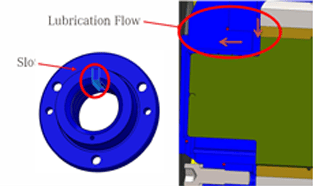

Additional Groove

- It is provided inside the cutting body to enhance lubrication of the shaft support bearing.

- This improves the lifespan of the shaft support and other interconnected internal component.

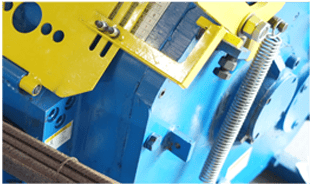

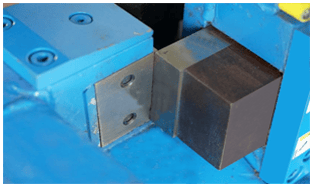

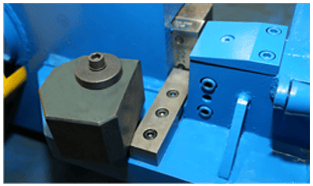

High Strength Blade

- High-strength blade made of tool steel material provided for cutting operation.

- Unique design allows the use of all four edges of the blade for cutting.

- One edge can process approximately 100 tons of material.

- Blade made from high-carbon, shock-resisting tool steel offers excellent wear resistance.

Movable Jig Locator

- The movable jig locator is equipped with a self-locking mechanism to ensure precise positioning and proper guidance of the TMT bar during cutting operations.

- This feature helps maintain accuracy and consistency in every cycle.

Energy Efficient IE2 Motors

- Italian-made energy-efficient IE2 motors with international warranty.

- Cost approximately 10% more than IE1 motors.

- Offer significant savings in running costs over their life cycle.

- Ensure higher energy efficiency, reduced operating expenses, and extended motor life.

Eccentric Shaft Support

The improved design ensures adequate oil lubrication within the shaft support, reducing frictional wear and extending the life of interconnected components.

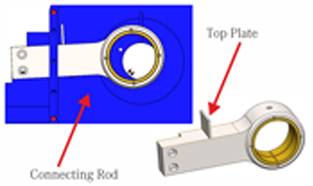

Connecting Rod

- The improved design of the connecting rod enhances oil splash inside the machine body, preventing flow at the blade exit.

- This lubrication increases component life, while the top plate further prevents oil leakage from the blade exit.

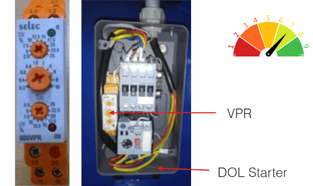

Voltage Protection Rating (VPR)

- Voltage Protection Rating (VPR) unit is installed inside the stator box.

- Protects the machine and motor from high and low voltage fluctuations.

Technical Specifications - Bar Cutting Machines

Capacity Charts - Bar Cutting Machines