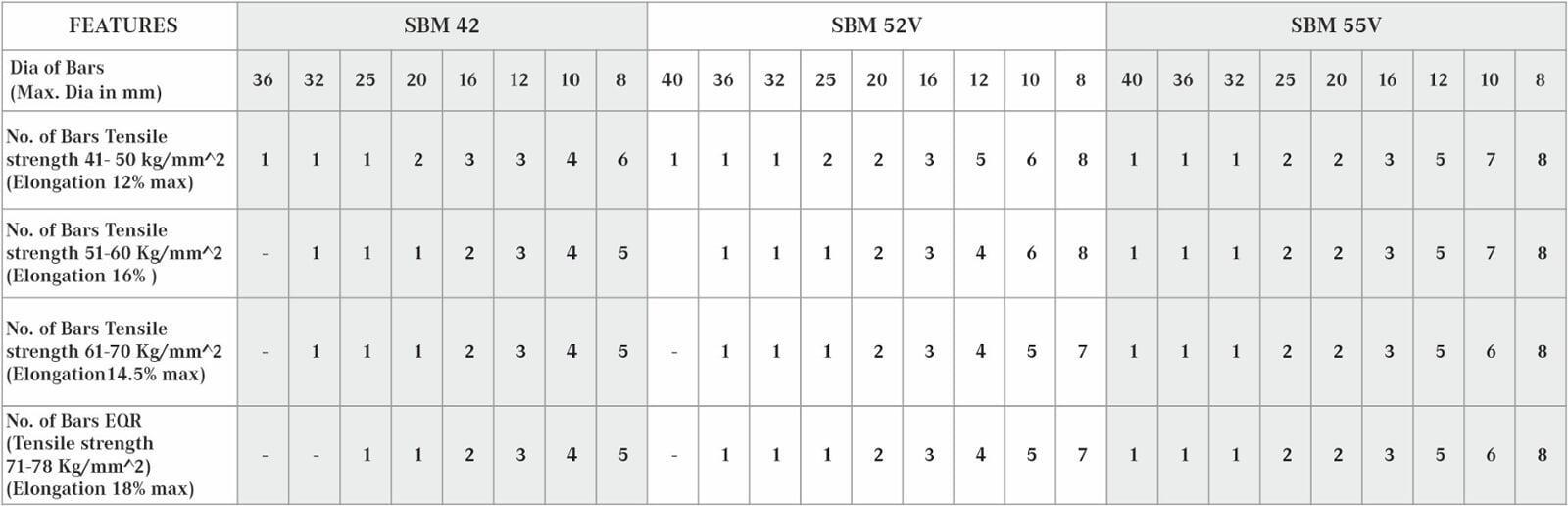

Bar Bending Machines - SBM 42

Bar Bending Machines - SBM 52V

Bar Bending Machines - SBM 55V

Salient Features - Bar Bending Machines

Body Frame Design & 7-tank surface Treatment

- Robust frame design with enhanced stability for bending operations.

- High-quality GI sheet construction with tough galvanization for durability.

- 7-tank treatment with pure polyester coating ensures durability, corrosion protection, and reduced maintenance.

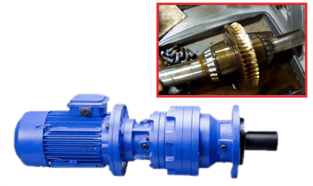

Planetary Gearbox with Grease Lubrication

- Planetary gearbox ensures easy assembly and low-maintenance operation.

- Direct motor drive reduces time, maintenance, and energy loss.

- Advanced grease lubrication for efficiency and durability.

Electric Panel with testing LV, HV

- LV-HV Test: Conducted to ensure the durability and sustainability of electrical components.

- Emission Test: Conducted to confirm that emissions are within permissible limits, posing no harm to the operator or the environment.

- Results: Zero breakdowns reported; tests were conducted by an authorized government testing body.

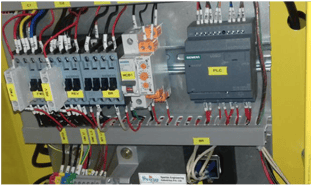

Advance PLC Control Panel

- Siemens/ Selec make PLC and safety logic to prevent over travel of bend wheel.

- During operation, if power shuts off, the machine halts in position. When power is restored, the bend wheel automatically returns to the home position instead of continuing forward, preventing accidents.

- Forward and reverse delay times are managed through the PLC for safe operation.

- Redundant components are eliminated, reducing the chances of breakdown.

- Wiring is minimized, making fault detection and troubleshooting easier.

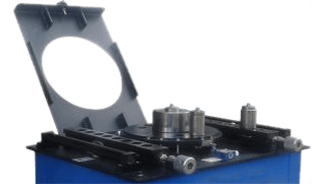

Cover for Bend Wheel

- Open and Close Top cover is provided for the bend wheel and limit switches.

- The top cover allows easy shifting of the machine at sites.

- It is specially designed to prevent rod dust from entering the bend wheel.

- The cover can be easily cleaned with a brush, ensuring smooth operation.

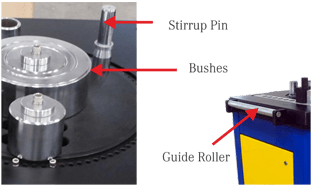

Keeper Plate, Guide Roller, Pin & Bushes

- Keeper Plate:

Ensures safe operation by securing the bushes & Prevents bushes from dislodging from the pin, enhancing operator safety during bar bending.

- Guide Rollers, Pin, and Bushes:

Constructed with high-strength, hardened material, features hard chrome plating to prevent rust and corrosion.

Hard Chrome Plated Pins

Components such as pins, bushes, rollers, and khob are provided with hard chrome plating.

Hard chrome plating ensures better surface quality.

It also offers effective rust prevention, enhancing component life.

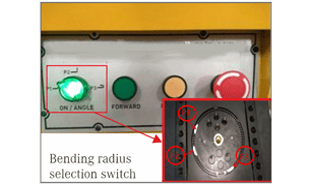

Three Bending Pre-selection

- Three bending radii can be pre-set, allowing different bend angles without removing the locator pin.

- The bend selector switch enables quick selection of the desired bend radius.

- The pre-selection switch makes operation twice as fast.

Work Hour Meter (Optional)

- A work hour meter is integrated into the Bar Bending Machine to track total operating hours.

- It helps in scheduling preventive maintenance.

- Assists in optimizing machine usage and ensuring efficient performance.

- Reduces downtime and enhances overall productivity.

Electric Foot Switch

- Foot switch is provided for easy and convenient operation.

- To avoid accidents, the foot switch must be pressed until the bend wheel returns to the home position.

- It ensures faster and smoother operation.

- Enhances operator comfort and ease of use.

- Foot switch enclosure is provided to protect the operator’s leg during operation.

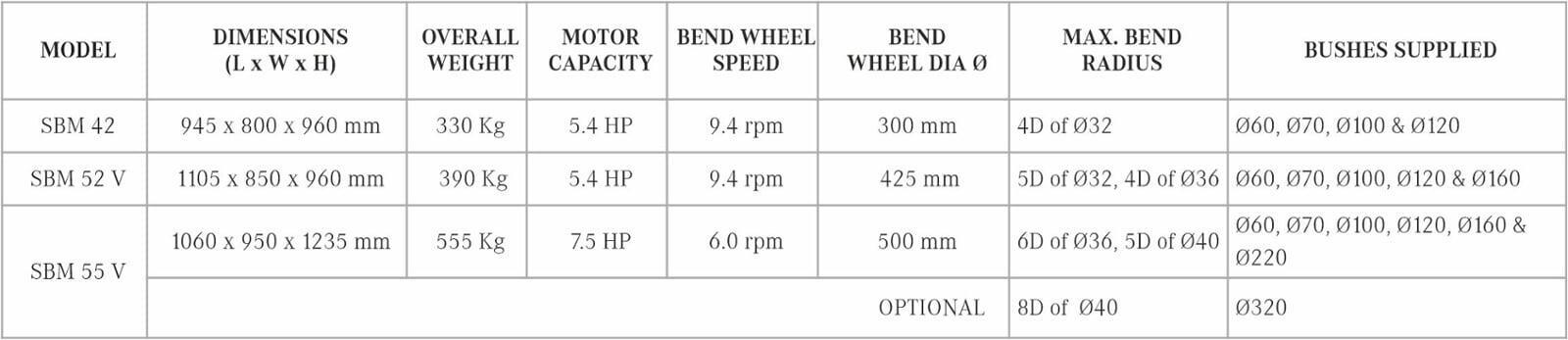

Technical Specifications - Bar Bending Machines

Capacity Charts - Bar Bending Machines